Knowledge Base

Mold Cleaner Safety and How to Use CUT Mold Cleaner Without Steel Wool

Mold cleaner safety is not a small process detail. In rotational molding, especially, how molds are cleaned affects worker health, tool life, and the quality of every part that comes out next. Yet one dangerous shortcut keeps showing up on production floors: pairing CUT Mold Cleaner with steel wool or Brillo pads.

![]()

Our experts want this message to land clearly and urgently: stop using steel wool or Brillo pads when cleaning molds. These abrasive tools are causing preventable injuries and creating avoidable damage that can permanently compromise expensive molds. There is a safer, more effective path, and it is simple to adopt.

Why Mold Build-Up Happens and Why Water-Based Cleaners Fail

Rotational molding molds live in harsh conditions. Long heat cycles, repeated release applications, and polymer fumes create a layered residue that builds up on metal surfaces over time. This baked build-up is rarely straightforward. It is usually a combination of:

- Degraded mold release that carbonizes under heat

- Polymer and additive vapors that plate onto hot steel

- Pigment carryover that clings in vent lines and texture

- Dust and fine debris trapped in micro-scratches

When operators reach for water-based mold cleaners, they often see the same frustrating result: the deposits smear, but do not lift. Water-based products cannot penetrate oily, carbonized, or wax-heavy layers very well, so the residue stays locked in place. That is when teams feel forced to scrub aggressively or even blast mold surfaces with particles. Blasting may remove build-up, but it can also permanently damage mold finish, texture, and venting. For high-value tools, that is an expensive loss.

CUT Mold Cleaner exists to solve this exact problem. It is a powerful precision mold cleaner designed to break down heavy, heat-baked contamination without requiring destructive methods.

What CUT Mold Cleaner Is Designed to Do

CUT Mold Cleaner is a fast-acting, non-chlorinated, non-citrus industrial mold cleaner explicitly formulated for metal molds. It dissolves release agents, grease, oils, carbon deposits, dirt, wax, and silicones, then flashes off quickly and leaves no residue when used correctly. It is engineered for precision mold cleaning, removing build-up while helping preserve the surface condition that controls part finish.

This is especially important in rotational molding, where surface integrity is directly tied to cosmetic quality and release consistency. CUT Mold Cleaner provides the chemical lifting power needed so operators do not have to “fight” the mold with harsh abrasives.

Download the Technical Paper to Learn More

The Real Problem: Steel Wool and Brillo Pads

Despite CUT Mold Cleaner’s design, some teams are still using steel wool or Brillo pads to scrub. Our experts have identified three serious consequences of this practice, all of which are preventable.

1. Hand injuries are happening

Steel wool is made of sharp metal fibers bundled together. When an operator pulls fibers apart to reach tight areas or applies pressure during scrubbing, those strands break, catch, and cut skin. The result is often deep finger cuts that require bandaging and can become recordable injuries. Beyond the immediate pain, this creates a workplace hazard that can lead to workers’ compensation claims and lost time, especially if infections or tendon issues develop.

2. Mold surfaces are being damaged

Steel wool is far more abrasive than many people realize. On polished or texture-critical molds, it can leave micro-scratches, soften edges, or roughen vent lines. Even light scratching can change how resin flows and releases, and over time, it shortens mold life. For tooling that costs thousands (or tens of thousands) of dollars, this is not a minor maintenance issue. It is a capital risk.

3. Metal residue contaminates the next part

Steel wool sheds. Those tiny metal fragments can remain on the mold surface even after wiping. In the next cycle, they transfer into the molded part as specks, streaks, or haze. That creates quality defects that are difficult to trace later, leading to scrap, rework, and customer complaints.

Steel wool and Brillo pads do not make CUT Mold Cleaner more effective. They only make the process more dangerous and more expensive.

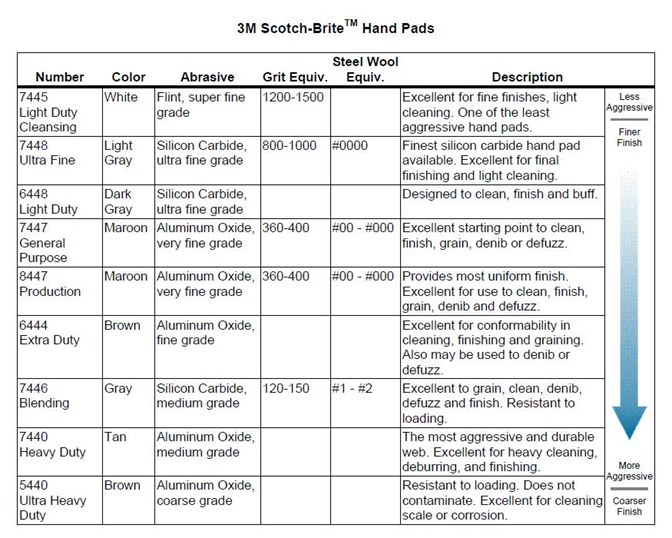

Scotch-Brite™ vs Steel Wool: The Safe Alternative

The recommended replacement is straightforward. Use a Scotch-Brite™ light scrubbing sponge, also called a pad.

Scotch-Brite™ pads are nonwoven nylon with a controlled abrasive load. They scrub consistently without shedding sharp metal fibers, and they allow operators to match abrasive level to mold finish. This protects hands and preserves mold surfaces while still removing lifted build-up.

If a cleaning station still contains steel wool or Brillo pads, removing them should be an immediate corrective action. Stock Scotch-Brite™ pads instead and standardize their use across shifts.

How to Clean Safely With CUT Mold Cleaner

A safer, more effective process looks like this:

- Apply CUT Mold Cleaner to the mold surface.

Spray it directly onto the metal mold, or apply it to a clean cotton cloth and wipe the mold. This targets contamination without over-wetting tight areas. - Let the cleaner work.

Give CUT Mold Cleaner a short dwell time so it can dissolve and release layers and carbonized residue. Rushing this step is what drives over-scrubbing. - Lightly scrub using a Scotch-Brite™ pad.

Use controlled passes and even pressure. Let chemistry do the lifting and the pad do the finishing. - Wipe clean with a cotton cloth.

Remove loosened contamination before it dries back onto the surface. - Reapply mold release after cleaning.

Once the mold is clean, apply fresh release. If a water-based release is used, cure it in an empty cycle to ensure proper cross-linking. This supports more pulls per application and reduces future build-up.

This method delivers mold-cleaning best practices without introducing unnecessary safety or tooling risks.

What Facility Leaders Should Do Next

Because this is a floor habit, it needs a management response, not a suggestion. Our experts recommend:

- Remove steel wool and Brillo pads from all mold cleaning areas.

- Post pad selection guidance and keep light Scotch-Brite™ grades stocked.

- Train operators on the correct CUT Mold Cleaner procedure.

- Audit cleaning stations during shift walks.

The benefits are immediate. Fewer hand injuries, fewer mold scratches, less residue transfer, longer mold life, and more consistent molded parts.

Download the Technical Paper and Reset Your Standard

If steel wool is still being used anywhere in your molding operation, the best time to stop is now. Download our PDF technical paper from the CUT Mold Cleaner product page and add it to your internal knowledge base. It includes a cleaning procedure, a helpful chart for pad selection, and the safety rationale needed to retrain teams confidently. For rotational molding plants and anyone managing high-value tooling, Stoner Molding provides CUT Mold Cleaner and the supporting safety resources to help you protect people, molds, and parts. Start now with your next cleaning cycle.

Shop Now

Unlike many mold release brands, Stoner Molding Solutions formulates, manufactures, and distributes our own products. Check out our full line of mold releases, sealers, cleaners, rust preventatives, and lubricants. In stock products are ready to ship now!