Purging Compounds: Minimize Downtime and Maximize Productivity in Thermoplastic Processing

How often do you discard molded products due to black specks caused by stubborn carbon buildup? Do your initial production runs after color or material changes consistently turn out discolored or defective? These issues are all too common in the injection molding, blow molding, and extrusion industries, where high heat and pressure can cause contamination if machines are not properly maintained.

Dirty or unclear equipment can lead to costly production delays, increased scrap rates, and unnecessary financial losses. The solution? Using high-performance purging compounds to clean your plastic processing equipment effectively.All Types of Purging Compounds for Every Process

When you work in industrial molding, you know that even the slightest chemical changes can completely ruin the entire run of a product. Purge compounds are invaluable for ensuring a clear and clean internal chamber for your injection molding, blow molding, and extrusion equipment.

Every facility has unique needs, and no one purging compound can work for every application. From processing to material type, dozens of small changes could influence your purging compound. Whatever your thermoplastic purging needs, our team can assist you in defeating your processing challenges.

CHEMICAL GRADES:

Our Premium Product Line for Challenging Applications

For extreme color changes or heavy carbon buildup, chemical purging compounds offer unmatched cleaning power. These solvent-based solutions break down the molecular structure of stubborn plastic residue, effectively cleaning it down to bare metal. This method ensures a fully cleared charge chamber with minimal effort, making it ideal for demanding applications in plastic processing.

MECHANICAL GRADES:

General Purpose, With or Without a Foaming Agent to Reach Negative Flow Areas

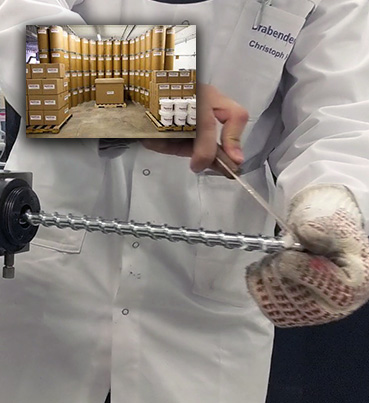

Mechanical grade purge compounds use Polyethylene as a carrier, combined with non-abrasive scrubbing and stiffening agents. Designed to clean old resin, color, and degradation from the barrel screw, these purging compounds offer a simple, effective solution. Run them through your equipment until purgings are clear, ensuring a reliable and hassle-free cleaning process.

FIBERGLASS-FILLED MECHANICAL GRADES:

For Powerful Cleaning Results

For thermoplastic processes that create heavy carbon and stubborn caked-on residue, glass fiber-filled styrenic purging compounds deliver superior physical scrubbing. These industrial purging compounds are formulated to tackle the toughest deposits, effectively removing carbon and buildup from processing equipment with maximum cleaning performance.

FDA/GRAS:

Chemical Product Line For Food/Medical Industries

Non-ammonia, non-foaming chemical/mechanical purge compounds are the ideal choice for sensitive applications. These products are designed for thermally activated purges and are made from FDA/GRAS-compliant materials. Their softening chemistry lowers resin viscosity, gently releasing residue for safe, effective cleaning in medical and food-grade processing environments.

Regardless of your purging compound needs, we can provide the powerful clean that you want! From baked-on and stubborn residue between charges to chemical cleaning to prevent cross-contamination, our RapidPurge compounds will ensure you continue confidently producing.

Choose from a Full Line of RapidPurge Purging Compounds

When you work with Stoner Molding, you gain access to purging compounds designed for every challenge in the industrial molding process. Each purge compound in our lineup is formulated to meet specific performance, convenience, and cost-efficiency needs. With more than 25 RapidPurge grades—including FDA/GRAS-compliant chemical purging compounds and custom solutions—we ensure you get the right product without confusion or stress.

Whether your facility struggles with carbon buildup, stubborn color changes, or material contamination, our experts are ready to help. If you have never used industrial purging compounds before, our team will guide you through every step. We understand that every plastic processing operation is unique, with different materials, methods, and equipment. That’s why we bring decades of hands-on experience to help you succeed.

Already using a purging compound but not getting the results you need? Let us troubleshoot your process. Our Technical Support team will analyze your application and recommend the best commercial purging compound for your specific situation.

Stoner Molding is Ready to Help

Are you ready to experience the difference that cleaner and more efficient equipment can make? Call us and get the purging compound that you need! Our high-quality purging compounds can provide a full suite of cleansing properties that will tackle your most specific and frustrating problems. If you have a question about our products or need help choosing one, call us.

Our team of experts will take the time to understand your application and assist in selecting the right purging compound to do the job properly. We ensure your complete satisfaction with our products by working alongside you every step of the way. If you aren’t sure if our products are right for you, call us and get a free sample! We can advise you on the right purging compound for your needs and ship you a sample so you can see the difference our purging compounds can make for you – get started today!