Knowledge Base

A Brief Guide to Mold Corrosion Control with Stoner Rust Prevention Sprays

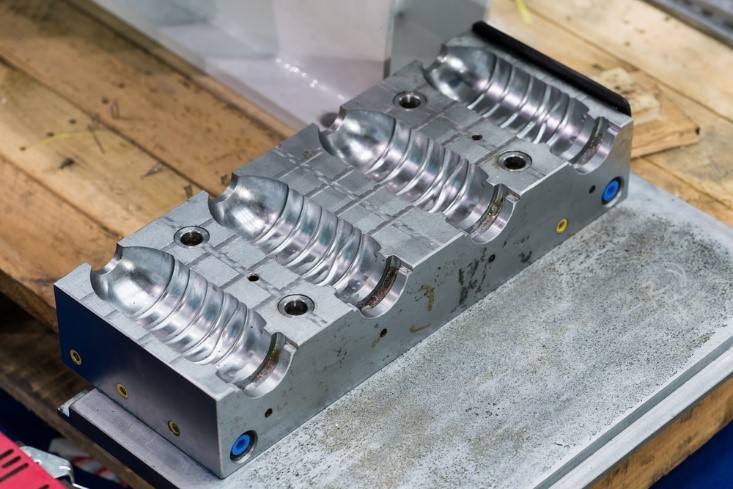

Whether your molding operation specializes in injection or rotational molding (or even some other type of molding process), it's true that preventative maintenance for hardworking molds typically centers around cleaning.

Whether your molding operation specializes in injection or rotational molding (or even some other type of molding process), it's true that preventative maintenance for hardworking molds typically centers around cleaning.

But that's not the whole story. Molds—especially Carbon steel injection molds—can develop rust or corrosion overnight.

No matter how thoroughly you clean and maintain your molds, if you're storing them for any length of time—or even allowing them to sit idle between production cycles—they're at risk of developing rust.

Similarly, using molds day in and day out can also make them vulnerable, as certain materials—like abrasive plastics—can wash away the mold steel after thousands of cycles. Also, in plastics manufacturing, materials with high-melt temperatures expose the mold to more heat and cause more wear versus plastics with low melt points. Some materials may create excessive residues or generate corrosive vapors that can lead to corrosion without proper rust prevention routines.

What's the Problem with Rust and Corrosion?

In short, rust and corrosion are extraordinarily costly. Rust is difficult to remove from nearly any metallic surface once it has been allowed to form, and that formation can render molds useless in some cases.

How Expensive is Rust?

Study results on the global economic impact of corrosion issues in industry by NACE International showed that the cost of corrosion each year is about $2.5 trillion (US). That's costs related to—or caused by—corrosion.

In many of the industries we work with here at Stoner Molding Solutions, costs related to mold damage and repair can quickly add up. However, rust and corrosion also cause damage to presses and other molding machinery, leading to manufacturing downtime and significant productivity loss.

If you have not set up a proactive mold maintenance program—including comprehensive corrosion control—your facility will run efficiently only until the next major rust-related problem or repair.

Why Remove Rust from Molds When You Can Prevent It?

As we mentioned, removing rust from mold surfaces is labor-intensive. And in some situations, it's nearly impossible due to the intricacy of individual cavities. What if you have to take a mold out of production prematurely due to rust? Your return on investment (ROI) in that mold will be poor.

The good news is that there's no need to allow your molds to suffer premature corrosion damage. Here at Stoner Solutions, we have developed several cost-effective rust prevention sprays. Read on to learn more about each of our four solutions designed to prevent rust for different periods of time—from overnights and weekends up to 1+ years in storage.

How to Prevent Rust Overnight and During Short Storage Periods

Our A612 Short-Term Rust Preventive product should be your go-to for protecting your valuable molds during short production downtimes, like overnights or through weekends when no one is molding.

A612 offers short-term protection against moisture and oxidation and prevents rust and corrosion from ruining exposed steel and stored metals. It also naturally wears off during the next production start-up, so there's no extra cleaning required.

The best part? A612—and all of our rust prevention products—are environmentally responsible. They contain:

- No chlorinated solvents such as methylene chloride or trichloroethylene

- No CFC or HCFC propellants or solvents

- No class I or class II ozone-depleting substances

How to Prevent Rust During Long-Term Storage or in Shipping

Do you need to ship molds or place them into storage? Or perhaps you need long-term protection for tooling or ejector pins? Choose between our two solutions for long-term rust prevention, A677 and A590, and put your worries about rust to rest for up to 12 months.

Both our A677 and A590 feature the following benefits. (A590 additionally contains a tracing dye that ensures even coverage of the product for better peace of mind.)

- Inhibits oxidation and corrosion

- Protects against moisture and dampness

- Adheres to metal surfaces without sagging

- Contains a built-in acid neutralizer for fingerprint acids (this benefit is not included in the A677 product)

- Protects steel and other metals

What About Medium-Term Mold Storage?

Not sure if you'll be storing your molds for an entire year or more? Our A592 Medium Term Rust Preventive product allows you to protect your molds against corrosion for several weeks.

A592 protects molds and exposed metal surfaces from moisture, oxidation, and corrosion. It also leaves a microfilm coating of penetrating lubricant and contains a built-in acid neutralizer that resists the damaging effects of mild acids, alkalies, and fingerprints.

Need more information?

Compare all of our rust prevention products side by side.

Download Our Rust Prevention Product Recommender

Reminder: Make Sure Molds are Clean Before You Store Them

At the start of today's post, we mentioned that keeping molds properly cleaned is critical to keeping your operation running smoothly and efficiently. If you're getting ready to store or ship used molds to another location, they must be clean before any rust preventative solution is applied.

Want to get our best mold cleaning tips? You'll want to check out our previous blog post on how to maximize mold performance with better cleaning and maintenance routines.

Prevent Corrosion on Your Molds—and Get Better ROI—with Stoner Solutions

Protect your molding operation's investment. From rust prevention to mold release, Stoner delivers tried and true solutions that keep your molds clean and maintained.

Schedule a call with one of our molding experts to learn how we can help you optimize your production and realize improved results and a better ROI with Stoner Solutions!

Shop Now

Unlike many mold release brands, Stoner Molding Solutions formulates, manufactures, and distributes our own products. Check out our full line of mold releases, sealers, cleaners, rust preventatives, and lubricants. In stock products are ready to ship now!