Knowledge Base

How to Use a Mold Release Spray

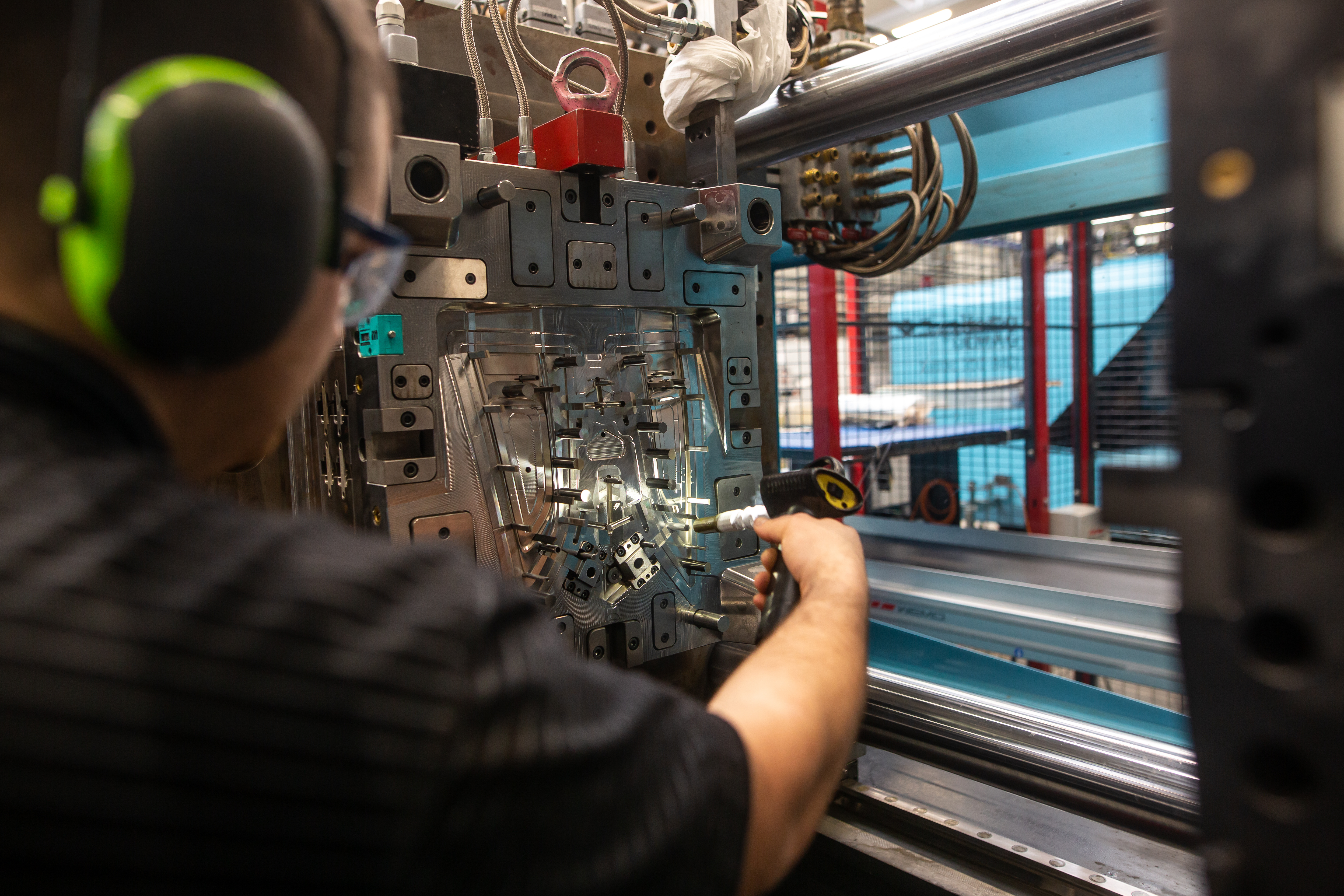

If you want more consistent results from your molding process, you want to use a mold release spray to ensure you experience as little damage and struggle as possible during the release process. While these products are designed around convenience and simplicity, don’t mistake that for a no-thought spray-and-go application.

If you want to get the most out of a product, take the time to learn how to use a mold release spray properly so that you ensure the successful and consistent release of your industrial molded goods time and time again.

The use of mold release sprays is not complicated, but multiple-minute steps can impact the success of this product's protective layer. Following these steps isn’t difficult but can have an outsized impact on the results of your molding process:

Prepare the surface

Thoroughly clean your mold’s surface with an industrial mold cleaning product – or a mild detergent in a pinch. A mold release spray forms an air-tight layer of protection, but any dirt and debris on the mold surface at application can cause poor adhesion or unintended damage during molding. This grime may even accelerate long-term damage like rust and hairline cracks.

Shake the Mold Release Spray Can

Shaking the can of mold release spray will agitate the product inside, ensuring that the pressure of the aerosol is even and high for consistent application across your mold’s surface. This also ensures the product inside is well mixed, reversing any settling since manufacturing.

Apply the Mold Release Spray Evenly

Hold the can of aerosol mold release spray about a foot away from the surface and apply a thin and even layer of the product across the mold surface. Apply this to the entirety of the working surface, but avoid over-spraying that might lead to pooling of liquid or uneven application.

Allow the Spray to Dry

Suppose you were to immediately begin molding after applying your water-based mold release. In that case, it may still be liquified, resulting in an unsightly surface or damage to the resulting molded goods. This time may vary depending on the humidity levels and spray type, so consult your product instructions for a better idea of how long to wait.

Reapply Between Uses

Not all mold release sprays are designed for use between multiple molding cycles, so it is advisable to re-apply after each release. Some of the products might stick to the molded good’s surface upon release or otherwise degrade during the molding process. Simply follow the application process again after each cycle.

Clean When You Are Finished Using Your Mold

Once you have finished your day’s work or are ready to swap molds, clean any leftover mold release spray residue from your mold’s surface using a mold cleaner. If you plan to store this mold for a time, use a rust preventative agent to protect your equipment from oxidation and long-term damage.

Mold Release Spray Tips

While the use and application of mold release can be simple, you can take some small steps to ensure that your application is safe, effective, and successful:

- Choose the Right Spray For Your Needs: Consult our experts to ensure that you use the appropriate mold release product for the materials you use, the process you employ, and the applications your goods are designed for. Water-based and oil-based sprays have very different usage, for instance.

- Use in Ventilated Areas: never use an aerosol in an enclosed area, especially a chemical product such as a release spray.

- Avoid Overspraying: Over-application of a spray can result in pooling, uneven application, or other issues that can result in your process's damaged or poorly molded results.

- Read Instructions: We understand that you might skip directly to applying your mold release spray, but reading the instructions and advice specific to the spray you chose can help avoid costly errors.

- Use Appropriate Protective Gear: During your process, you should use protective gear such as gloves, goggles, and masks to protect yourself from the product. Your eyes, skin, and respiratory system are particularly important and sensitive to chemicals of this nature.

- Store Mold Release Spray Appropriately: When not in use, tightly close the canister of mold release spray and store it in a cool, dry place that is out of direct sunlight and away from heat/flames. Consult your product manual for more specific information.

A mold release spray for your process will provide a faster and easier process. This, in turn, gives you a more productive and efficient business! A simple spray can improve Your bottom line by reducing the amount of rejected goods and wasted materials. If you’re ready to get started, call us!

Get Your Mold Release Spray From Stoner Molding Solutions!

If you have ever struggled with the demolding process – wasting material and causing rejected goods – then you know the value of a mold release spray. The frustration of low-margin work like molded goods is that every small error in production has an outsized impact on your bottom line. Using mold release spray will help you avoid common damages and errors and allow you to work more confidently and consistently!

The molded goods industry has a mind-boggling number of materials, processes, treatments, and more combinations. Our team of experts can help you choose the right products for your process. If you already have a handle on things, see our product inventory and get started!

Shop Now

Unlike many mold release brands, Stoner Molding Solutions formulates, manufactures, and distributes our own products. Check out our full line of mold releases, sealers, cleaners, rust preventatives, and lubricants. In stock products are ready to ship now!