Rubber Molding and Its Importance in Modern Manufacturing Techniques

Rubber molding has evolved from a straightforward manufacturing method into a precision-driven craft that powers the automotive and aerospace industries. The difference lies in advanced techniques, including mold release products, that cut production time, minimize waste, and deliver unmatched consistency. For manufacturers aiming to stay competitive, understanding these methods is the key to producing high-quality components faster and more cost-effectively.

The Evolution of Rubber Molding Techniques

For decades, manufacturers relied on tried-and-true processes to shape rubber into functional products. While the core principles remain the same, today’s rubber molding techniques incorporate innovations that maximize productivity and product quality. Improvements in machinery, material science, and process automation have made it possible to meet stricter tolerances, achieve more complex designs, and reduce turnaround times.

Modern facilities now integrate computer-controlled systems, advanced tooling, refined material formulations, and the proper mold releases to ensure every molded product meets precise specifications. These advancements are particularly beneficial for aerospace, automotive, healthcare, and consumer electronics industries, where consistency and reliability are critical.

Understanding the Types of Rubber Molding

Different applications require different types of rubber molding, each offering unique benefits depending on the product’s complexity, production volume, and performance requirements. The three most widely used methods are injection molding, compression molding, and transfer molding. Each process has evolved with innovations that improve speed, accuracy, and material efficiency.

Injection Molding

Rubber injection molding is ideal for producing high volumes of intricate components with tight tolerances. Preheated rubber is injected into a mold cavity under high pressure, ensuring even distribution and minimal waste. Modern injection molding machines have precision controls that regulate temperature and pressure, producing consistently high-quality parts.

The technique’s efficiency is particularly beneficial for industries that demand repeatable results and fast cycle times. With automation and robotics now integrated into production lines, manufacturers can further increase output while maintaining quality standards.

Compression Molding

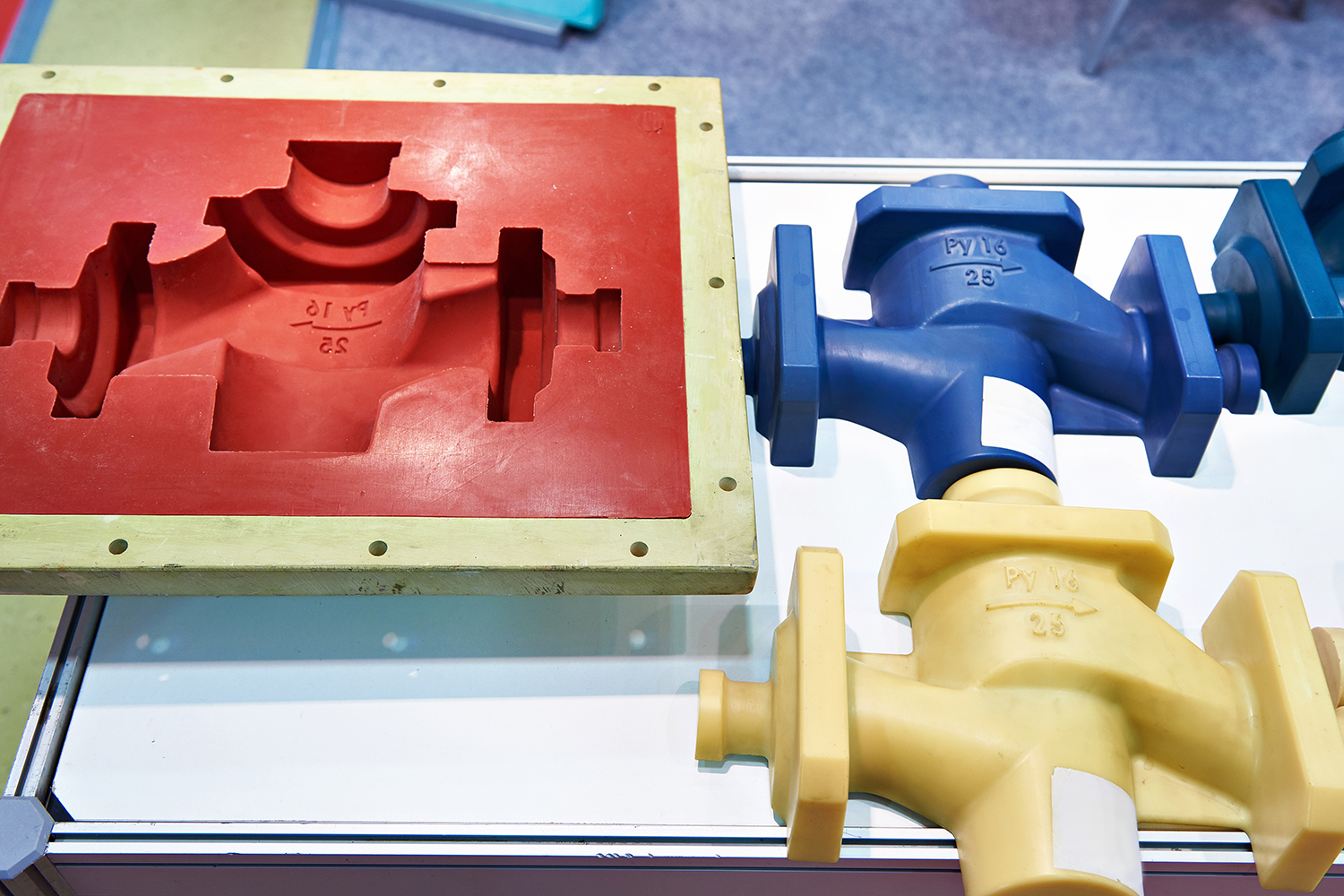

Compression molding remains one of the most reliable rubber molding processes, particularly for larger parts or applications where material integrity is a priority. Pre-measured amounts of rubber are placed into heated molds, then compressed under pressure until the material fills the cavity and cures.

Recent advancements include improved mold design for better heat distribution, allowing faster curing and more uniform results. While compression molding may not match injection molding’s speed, it excels in durability, making it a preferred choice for heavy-duty industrial components.

Transfer Molding

Transfer molding blends features from both compression and injection methods. Rubber is first placed in a chamber and then forced through channels into the mold cavities. This process is ideal for producing complex parts with inserts or intricate details, offering greater design flexibility.

Recent improvements include optimized flow paths to reduce air entrapment and material waste. These changes not only enhance product quality but also shorten production times, allowing manufacturers to meet demanding schedules without compromising performance.

Innovations Driving the Rubber Molding Process

Advancements in rubber molding techniques go beyond equipment upgrades. New mold coatings reduce sticking and facilitate faster part release. Computer-aided design (CAD) and simulation software enable engineers to fine-tune mold geometry before production begins, minimizing trial-and-error adjustments.

Additionally, automation in quality control ensures that each part meets specifications without slowing down the production line. Machine learning and real-time monitoring also help detect and correct process variations early, reducing scrap rates and improving efficiency.

The Role of Rubber Molding Materials

Choosing the right rubber molding materials is just as important as selecting the right process. Material innovation has produced compounds that can withstand extreme temperatures, resist chemical exposure, and provide superior flexibility or rigidity, depending on the application.

From natural rubber to advanced synthetic elastomers like silicone, EPDM, and nitrile, manufacturers can tailor their material choices to enhance product performance while ensuring cost-effectiveness. The right combination of material and process results in parts that last longer, perform better, and meet exact industry requirements.

Operational Benefits for Businesses

When businesses adopt advanced rubber molding techniques, the rewards go beyond product quality. Faster production cycles mean quicker time-to-market, vital in industries where speed can be a competitive advantage.

Reduced waste and optimized material usage translate into significant cost savings over time. Moreover, consistent quality reduces the risk of product recalls or performance failures, strengthening customer trust and brand reputation. These operational advantages make modern rubber molding a smart investment for companies looking to stay competitive.

Partner with Experts for Proven Results

No matter which rubber molding techniques a manufacturer uses, the quality of the final part often depends on more than just the mold and the material. Reliable mold release products are essential to preventing sticking, reducing scrap, and ensuring consistent finishes. By using the right solutions, manufacturers can streamline production, extend the life of their molds, and protect the integrity of each part.

Enhance Your Manufacturing with Stoner Molding

For businesses committed to achieving the best results from their rubber molding process, the right mold release products make all the difference. Stoner Molding provides advanced solutions that keep production moving smoothly, minimize downtime, and improve part quality. Our products are designed to help manufacturers reduce waste, lower costs, and maintain precision across every run. Contact us today to learn how Stoner Molding's mold release products can give your operation a competitive advantage.